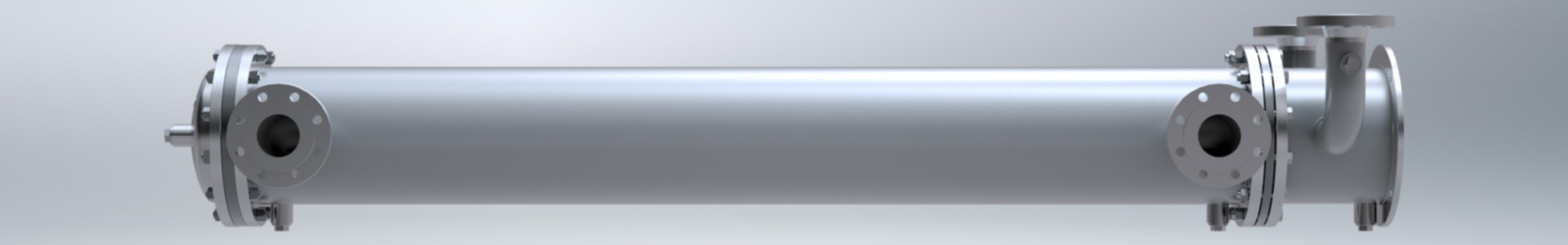

Made in Gunzenhausen

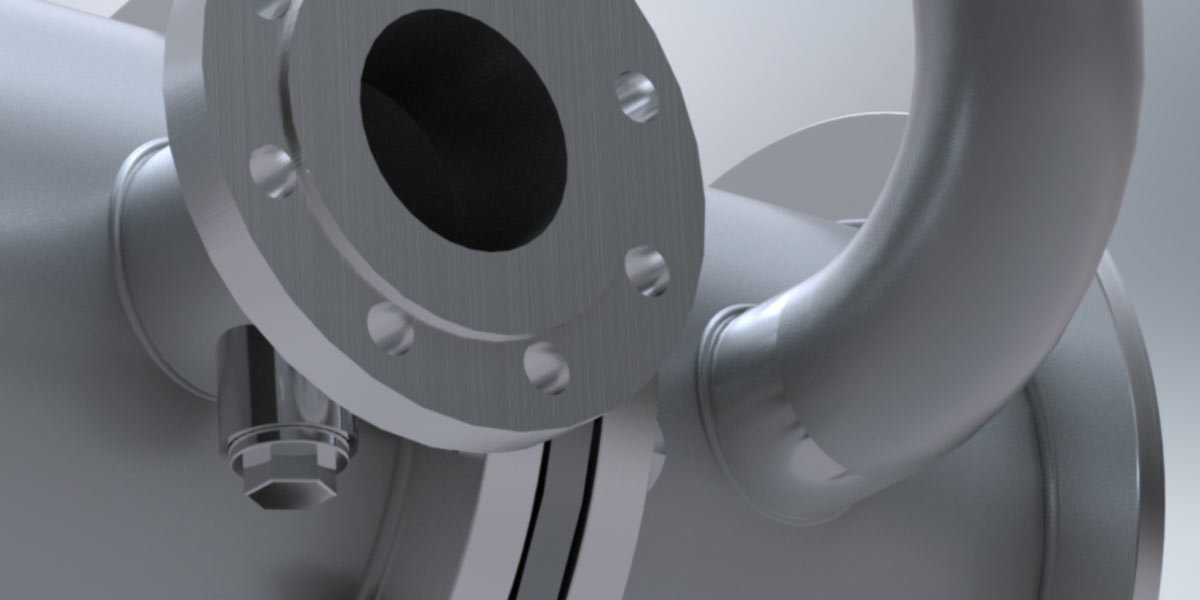

The technically sophisticated Hering products are always “customized solutions” and provide our customers with a wide range of custom process-oriented solutions.

With an integrated process chain – which extends from in-house engineering to in-house production – our heat exchangers are the result of the “We are Hering” philosophy and bear the designation “Made in Gunzenhausen/Germany”.

Hering AG products are characterized by durability, high plant availability, and a high level of reliability, according to testimonials by our international clientele.